Real-world energy savings obtainable from load vs. lift Variable speed drives (VSDs) can cut a chiller’s annual energy use by up to 30 percent while maintaining operating reliably over a wide range of condition. This is accomplished in two ways:

• At part load when cooling capacity can be reduced, a VSD chiller inherently uses less energy than a constant speed chiller whenever the compressor speed can be reduced to more closely match the load.

• At low-lift conditions, when either tower water temperatures can be reduced or chilled-water-supply temperatures can be increased, up to four times more energy can be saved if the VSD chiller is designed to operate in these off-design conditions.

Chillers rarely operate at their full-load efficiency rating, because conditions vary. Accordingly, the U.S. Environmental Protection Agency (EPA) recommends installing VSDs on centrifugal chillers, because “this will allow the chiller to run at lower speeds under part-load conditions, thereby yielding a higher efficiency than is typically achieved by ordinary centrifugal chillers that control part-load operation with inlet vanes.”

Using chillers with VSDs is a proven way to optimize energy utilization at full and part load,as well as under design and off-design conditions at varying ambient temperatures. Because more energy is saved if a chiller can operate with reduced tower water temperatures compared to reduced capacity only, it's worth examining both scenarios closely.

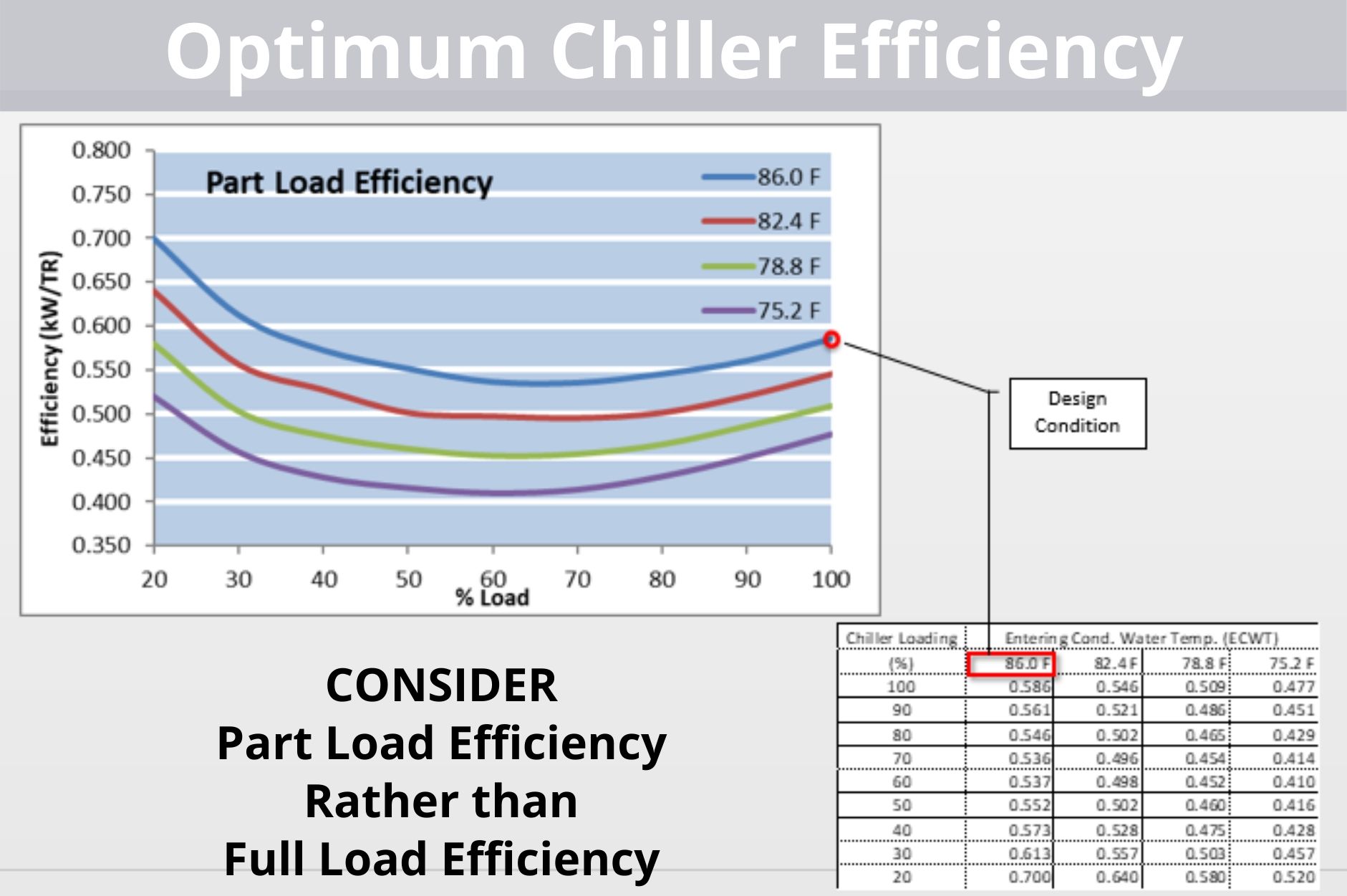

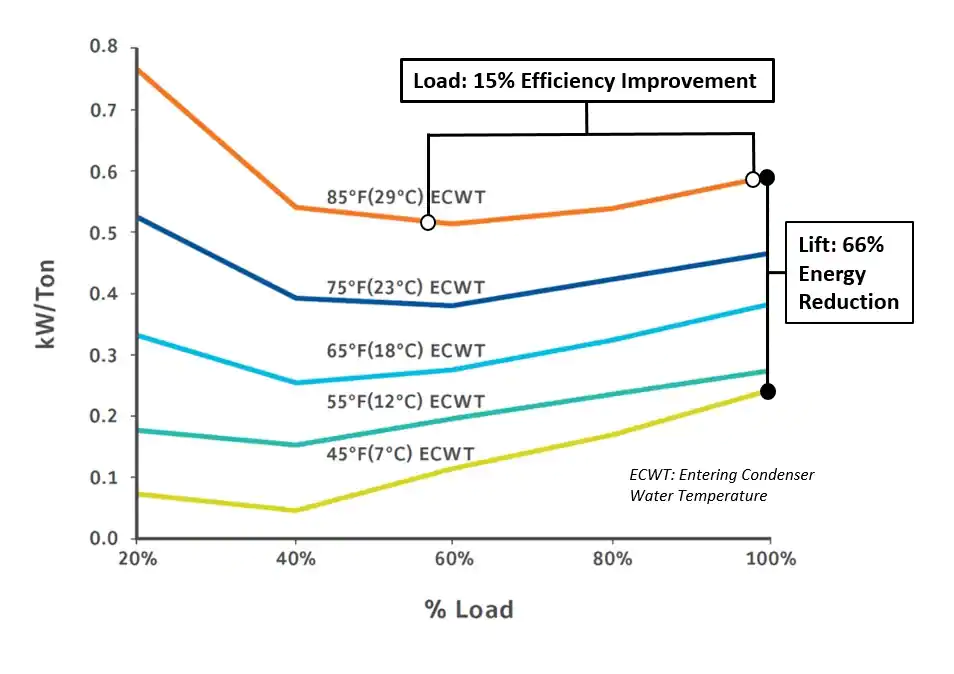

Two Variables in Energy Savings • Of course, the cooling load (capacity) is a factor affecting chiller energy consumption. As shown in Figure 1, when a chiller at a constant entering condenser water temperature (ECWT) can reduce load (Btu/hr) by 50 percent, its efficiency (kW/ton) at the new condition improves by 15 percent. • But the main factor that affects VSD chiller energy consumption is “lift.” Lift is defined as the difference between the evaporator pressure and condenser pressure. The thermodynamics of lift has a profound impact on a chiller’s energy consumption

Chiller load is the amount of cooling the chiller provides, while lift determines how hard the chiller must work to deliver the cooling. The greater the difference between evaporator and condenser pressures, the greater the lift and the more work the compressor must perform. By reducing the lift, more energy savings can be realized.

Chat with us

Chat with us